Tailings storage facilities (TSFs) and embankment dams play a vital role in the mining and infrastructure sectors, serving as impoundments for the storage of waste materials and water, respectively. The seepage of water through these structures presents a significant stability challenge, with potential geotechnical, environmental and safety implications. Traditionally, seepage monitoring methods have primarily relied on groundwater monitoring wells, piezometers and downstream weirs/flumes. However, temperature cables, while not commonly deployed for seepage monitoring, offer a promising solution. In this blog post, we will explore how temperature data from these cables can serve as a valuable tool for monitoring seepage in tailings storage facilities and embankment dams, providing a more cost-effective and efficient approach.

Tailings dams are reservoirs used to store waste materials generated from mining activities, such as rock fragments, which have often been crushed into sand and fine grained particle sizes, and liquid discharge. While these dams serve a crucial purpose in managing waste, the seepage of liquids can lead to geotechnical instability of these structures and can pose a significant environmental risk if contaminated fluids seep into the surrounding area. According to the latest statistics, approximately 3,500 tailings dam facilities exist globally, with a substantial number displaying signs of seepage issues. In fact, a recent report indicated that more than 10% of active tailings dams have experienced concerning levels of seepage, leading to potential contamination of nearby water sources (Piciullo, et. al., 2022). These alarming figures call for immediate action and emphasize the need for effective monitoring systems.

Understanding Dam Seepage

Understanding the dynamics of tailings dam seepage begins with acknowledging the seasonal temperature variations within impounded water in tailings ponds or reservoirs. As water permeates through the dam, it carries the temperature signature of the reservoir, providing a unique opportunity for monitoring using temperature cables. Detecting changes in seepage is vital for safeguarding dam safety and environmental integrity, as any breaches can result in severe downstream consequences, including fatalities, infrastructure loss, water source contamination and habitat destruction. It’s important to recognize that seepage, inherent in all dams, must be carefully managed to control both its velocity and quantity. Seepage can manifest anywhere on the downstream face, beyond the toe, or on the downstream abutments (EGLE, n.d.).

According to a study by Yun, Butler, and MacQuarie (2023), ‘Seasonal subsurface temperature monitoring, which exploits the fact that increased seepage flow may locally alter the temperature distribution, is a useful approach for leakage monitoring and evaluation within embankment dams and their foundations’ (p. 1).

Therefore, leveraging temperature data to detect and model seepage is crucial for ensuring the long-term sustainability and safety of tailings storage facilities and embankment dams.

Using Temperature Cables for Seepage Monitoring

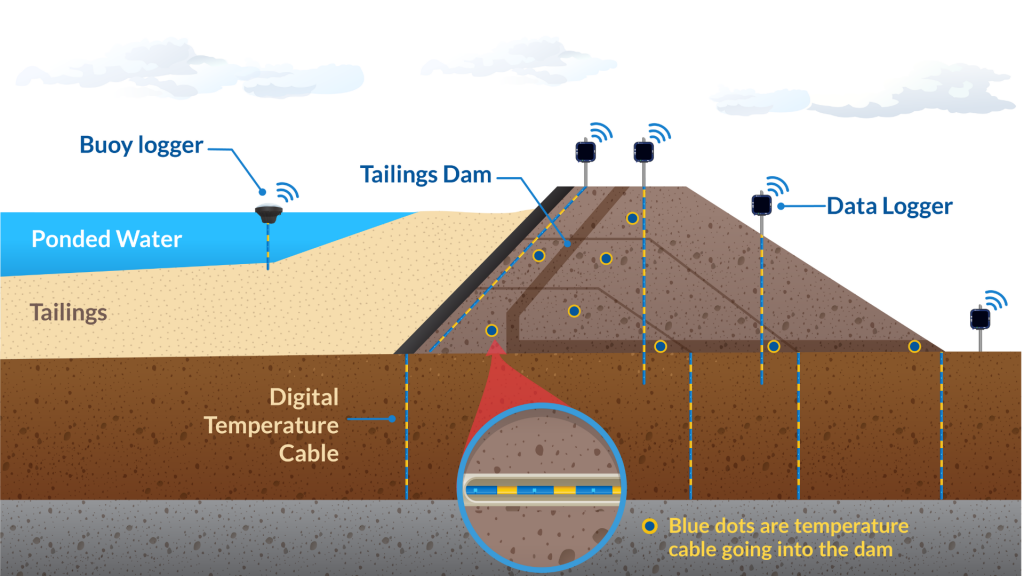

Temperature cables serve as a sophisticated tool for monitoring seepage in TSFs and embankment dams, leveraging their unique capabilities to detect subtle changes in temperature. These cables typically consist of multiple thermistors distributed along their length, allowing for precise measurement of temperature variations. The installation process of temperature cables within dams varies depending on the construction phase. During initial construction, horizontal installation is integrated into the dam structure, providing continuous monitoring capabilities from the outset. For existing dams, temperature cables can be retrofitted into abandoned standpipes or inclinometer casings, or buried horizontally along the toe, avoiding the need for extensive drilling. This retrofitting approach minimizes disruption to the existing infrastructure while enhancing the dam’s monitoring capabilities. The aim is to create a grid of temperature sensors within the dam to detect spatial temperature changes due to water flow (See Fig. 1).

The significance of capturing spatial variability of seepage cannot be overstated, as it provides critical insights into the integrity of the dam structure. By strategically placing multiple thermistors along each cable, engineers can monitor seepage changes and patterns with precision, enabling thermal modeling of the structure and leading to proactive intervention when necessary. Additionally, recording reservoir temperature serves as a vital reference point for comparing temperature variations within the dam. This comprehensive approach to temperature cable installation and monitoring facilitates efficient and cost-effective seepage detection, ensuring the continued safety and stability of TSFs and embankment dams.

Digital Temperature Cables (DTCs) vs Distributed Fiber Optic Systems (DFOS)

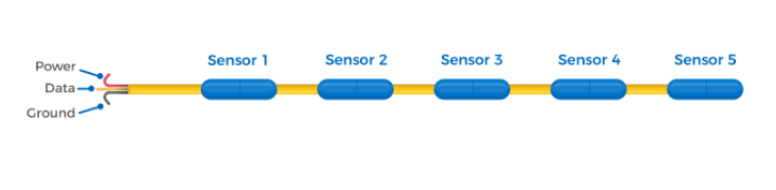

According to the Canadian Dam Association’s webinar1 on Detection of Seepage through Dams/Abutments using Non-Destructive Investigation Techniques (2023), Digital Temperature Cables (DTCs) and Distributed Fiber Optic Systems (DFOS) stand as two prominent methods for temperature monitoring in dam seepage detection. DFOS, although sporadically implemented in practice and more prevalent in the literature, is commonly utilized in Swedish dams. It provides extensive coverage, featuring fiber optic sensor cables that span several kilometers and offer continuous measurements along their length. DTCs instead provide a practical alternative with distinct advantages. beadedstream’s DTCs, for instance, utilize 1-wire technology, enabling up to 125 discrete, digitally addressable sensors on a single cable (with user defined spacing), all powered and transmitting data through the same set of 3 conductors (See Fig. 2). This innovative design allows for tight, although not continuous, measurements of temperature of lengths of up to 750m.

DTCs can be connected to simple geotechnical data loggers, including the same or similar models already in use to read other dam instrumentation such as VW piezometers, in-place inclinometers and SAA’s, for a seamless monitoring experience. DFOS, on the other hand, requires an interrogator to monitor the cables which can be cost prohibitive for many projects. The data output from a DTC is a simple array of temperature data in °c or °f, while DFOS requires specialized data interpretation of the raw output to result in temperature readings.

Despite DFOS’s continuous monitoring advantages, it comes with certain complexities, including costly installations, intricate data processing, and advanced technological understanding requirements. Conversely, temperature cables present a simpler and more cost-effective solution, enabling straightforward installations and integration at any phase of the project (Mohamed, et. al., 2021). This makes them particularly advantageous for dam seepage monitoring, where the ability to detect subtle temperature changes with precision is paramount for early intervention and mitigation.

Monitoring Seepage with Temperature Data

Monitoring seepage with temperature data involves a meticulous process that utilizes the capabilities of digital temperature cables to measure seasonal variations as water permeates through the dam structure. Equipped with multiple sensor points at regular intervals, these cables accurately capture temperature fluctuations, providing insights into the movement of impounded water within the dam. These fluctuations include spatial and temporal changes. By monitoring these variations over time, engineers can detect subtle changes indicative of seepage, facilitating early intervention and mitigation measures to uphold dam integrity and environmental safety.

One crucial aspect of temperature-based seepage monitoring involves analyzing the time offset between temperature readings within the dam and those recorded in the reservoir. The temperature in the reservoir changes seasonally, depending on the location’s climate, and the water seeping through the dam carries this seasonal temperature to the location of the temperature sensors. Monitoring this time offset from the reservoir to each sensor, to establish a baseline, allows engineers to observe changes from this standard.

Maximizing the Value of Thermal Data

Harnessing the insights gained from temperature-based seepage monitoring, engineers and consultants can take proactive steps to ensure the structural integrity and safety of embankment dams. By employing advanced numerical modeling techniques, such as finite element methods, they can delve into the complexities of thermal behavior within the dam body. These models enable the simulation of heat conduction, advection, and dispersion, providing a comprehensive understanding of seepage dynamics (Yousefi, et. al, 2013). Armed with this knowledge, engineers can estimate quantities of seepage flow rates and predict potential leakage, crucial for assessing dam safety.

Furthermore, engineers can leverage the power of thermal data to optimize monitoring strategies. By analyzing temperature fluctuations over time, they can detect subtle variations indicative of seepage, facilitating early intervention and mitigation measures. Monitoring the time offset between temperature readings within the dam and those in the reservoir allows for real-time assessment, promptly identifying potential issues. Moreover, observing temperature changes within specific areas of the dam provides valuable insights into flow patterns and potential breach points, enabling targeted interventions to address seepage effectively. Through the strategic utilization of thermal data and advanced modeling techniques, engineers can proactively safeguard dam infrastructure and environmental integrity.

Taking Action Based on Monitoring Data

Timely intervention is paramount in mitigating the risks associated with seepage. Engineers interpret temperature data rigorously, implementing tailored mitigation strategies to address identified issues promptly. These strategies may encompass reinforcing dam structures, adjusting operational procedures, or augmenting monitoring measures to bolster the facility’s resilience against seepage-related risks. The proactive use of temperature data empowers decision-makers to safeguard critical infrastructure and surrounding ecosystems from potential harm.

Conclusion

In conclusion, the utilization of temperature cables offers a cost-effective and efficient solution for seepage monitoring in TSFs and embankment dams. When combined with complementary monitoring instruments and systems, such as piezometers and remote sensing technologies, temperature-based monitoring methods provide a holistic approach to assessing dam integrity and mitigating risks effectively. beadedstream stands at the forefront of this innovative landscape, offering digital temperature cables, data loggers, and the capability to seamlessly connect to major 3rd party data loggers already in use in many tailings and embankment dams. Additionally, beadedstream provides a cloud-based temperature data monitoring dashboard called beadedcloud, facilitating real-time monitoring and analysis of temperature data for enhanced decision-making. For inquiries or collaboration opportunities, please contact us at contact@beadedstream.com.