Mining

Applications for Mining Industry.

Mining

Mining operations alter the natural environment and require monitoring to understand this impact, as well as the stability of the mine’s assets. Mines in the north often utilize the cold region conditions to operate frozen waste facilities but changing climate conditions challenge whether they will stay in a frozen state. Mines operating all over the world manage massive waste facilities where understanding the internal characteristics is vital for maintaining safe operations. Understanding how mining impacts the surrounding environment is also vital. Mining applications include:

Permafrost characterization

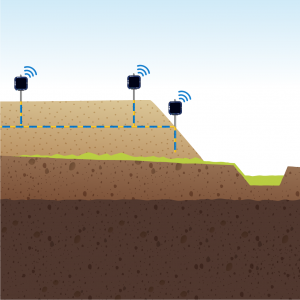

Mines under exploration, construction, operation or expansion in permafrost regions need to understand the background temperature profiles of the permafrost and the impacts their activities have on it over the mine’s life. Any infrastructure built over permafrost such as haul roads, tailings storage facilities, mills, etc. can be impacted by permafrost thaw if slumping or differential settlement were to occur.

Environmental assessments for obtaining government permits to develop and operate the mine also require background monitoring of the natural conditions and continued monitoring during operation to determine any impacts from mining activities.

A permafrost monitoring program consisting of ground temperature cables and data loggers allows the mine owner to understand the conditions at their site over time.

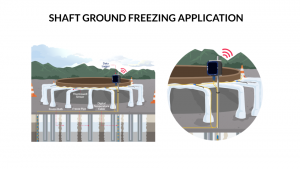

Artificial Ground freezing

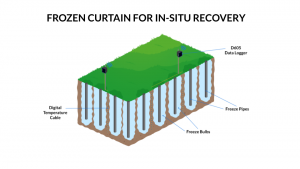

Artificial ground freezing in mining involves chilled liquid circulated through vertical pipes in the ground, freezing porewater and creating a freeze bulb around each pipe. The pipes are installed in closely spaced patterns so freeze bulbs can grow and merge together to create a frozen underground wall. The purpose of the freezing is to prevent groundwater flowing in, to prevent contaminated water from flowing out and/or to improve the stability and mechanical properties of ground conditions.

It has been used for underground uranium mining operations and potash mine shafts, where the target zone can be up to 1000 m/ 3281 ft below ground surface, and the designed frozen volume can be as large as the entire ore body plus the overburden combined. Alternatively, a crown pillar can be frozen by drilling and installing freeze pipes upwards from an underground opening.

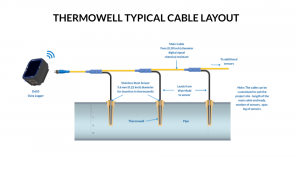

Freezing of the ground can take years (vs. weeks for infrastructure applications), requiring long-term monitoring of the freeze bulb development. Similar temperature cables are used to profile the ground but due to the high water pressures often encountered at these depths, and potential exposure to corrosive heat exchange fluids, such cables are typically installed inside a sealed conduit to provide additional protection during the duration of the freeze program.

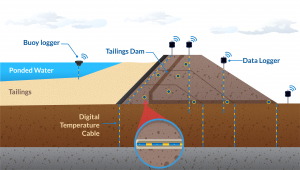

Tailings Dam Seepage

While perhaps not an intuitive use for temperature cables, temperature data can provide another tool for monitoring seepage of tailings storage facilities (TSF) and other embankment dams/levees. Impounded water seasonally varies in temperature and when it leaves the tailings pond or reservoir and travels through the dam, it will carry the temperature of the tailings pond/reservoir. These temperature signatures can be used to detect seepage more easily and more cost effectively than other means.

Temperature cables can be installed within the dam either horizontally, as the dam is built, and/or vertically, either during or after construction. For existing dams, the cables can be grouted into abandoned standpipes or inclinometer casings, or buried horizontally along the toe, avoiding the need to drill. To capture spatial variability of seepage, many thermistors are typically installed along each cable, spaced close enough for the dam engineer to monitor seepage changes and patterns. Horizontal cables are often installed at multiple elevations to monitor vertical variability. The reservoir temperature is also recorded for reference.

As water seeps through the dam, the temperature cables measure the seasonal variations, albeit with a time offset from the temperatures observed in the reservoir. Dam engineers monitor the data for changes in this time offset because a shorter time period can be an indication of increased seepage. Also, temperature changes within a particular area of a dam can indicate a change in the flow path. If changes are observed, the engineers can take action to investigate further and implement any required mitigation strategies.

Tailings Dams with a Frozen Foundation/Core or Frozen Deposits

Tailings dams built on permafrost can be designed assuming that the foundation will remain frozen forever and/or the core of the dam will freeze after placement and remain in that state. Or passive cooling methods such as thermosyphons may be employed to help the ground remain frozen. These design assumptions rely on the frozen ground for containing the tailings in perpetuity. But the warming climate, especially in the north, is challenging that assumption.

Understanding the temperature profiles in the foundation and within the embankment are critical for observing the performance of the dam during construction and long-term during operation and eventual closure. The temperature cables can be installed vertically into drill holes in the foundation prior to construction and additional cables buried within the embankment during construction of each lift of the dam. The data collected can be used to model future temperature profiles within the ground and to allow the mining company and the tailings dam Engineer of Record to act in advance to mitigate any warming trends observed.

Tailings deposited in winter, at sites below freezing, can freeze at surface and subsequently get buried by later deposits. The later deposits act as insulation, preventing the thaw of the buried frozen layers during warmer months. Over time, these lenses grow in number and result in reduced storage room, since the frozen tailings take up more room than the equivalent thawed material would. It also creates issues during closure and reclamation of the facility. Understanding the extent of these lenses via temperature monitoring and understanding the effectiveness of mitigation efforts is critical during the operation and closure stages of these facilities.

Acid Mine/Rock Drainage in Waste Dumps and Tailings

Acid mine/rock drainage can occur in waste dumps, tailings storage facilities or dry stack tailings , or in other exposed rock in mine workings, when sulfides oxidize after being exposed to oxygen and water. Acid generation can occur over many decades and can contaminate the surrounding environment when acidic waters flow from the mine workings. These acidic waters can also mobilize heavy metals and transport them into the environment, affecting local plants, animals and waterways.

The sulfide oxidation process can be monitored by insitu instrumentation, including temperature cables, to look for increased temperatures indicative of the process. These temperature cables are installed within monitoring wells in the waste dump or TSF, with each cable having multiple thermistors at different depths. The resulting temperature data can help in identifying hot spots within the facility, both via depth along each cable and across the facility via installing multiple cables, and allow the project staff to assess areas of concern and take further steps to address the acid generation.

Environmental Conditions

Disturbance of the local environment around a mine site is inevitable during exploration, development and operation of the mineral resource. But mining companies have a duty, either via local regulations or ethically, to reclaim the lands back to nature including waste dumps and tailings storage facilities.

Understanding the background environmental conditions of permafrost, waterways and groundwater is important to collect during exploration and early phases of the mine. During construction and operation, environmental monitoring is required to observe, mitigate and remediate any side effects from mining activities to the surrounding lands. Reclamation efforts also require monitoring to ensure the efforts will lead to a sustainable return of the land back to the environment.

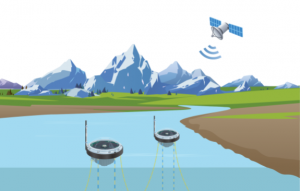

Monitoring of these environmental conditions, such as hydrology (lake/pond/stream/ditch profiles and precipitation infiltration through reclamation liners) at mine sites mirror our Environment applications and you can visit this page to learn more.

Heap Leach

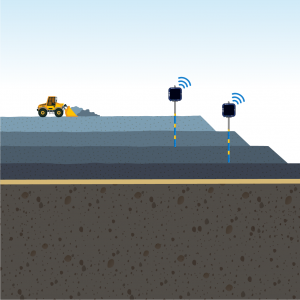

Understanding solution flow through heap leach pads is vital to operations engineers to ensure the optimization of their heap leach process. In cold regions, the risk of the solution freezing is an added challenge for the operation. Monitoring the temperature of the solution can help engineers understand the current conditions and implement mitigation processes, such as solution heaters, minimizing the potential operation impacts during the winter.

In all regions, temperature data can be used to monitor where the chemical and biological reactions of the leaching process are occuring within the pad, giving operators an insight into what is happening below the ground surface.

Cold Region Dry Stack Tailings

Dry stack tailings are gaining prevalence in the mining industry for tailings storage due to their increased stability, reduced water storage and footprints, compared to traditional tailings storage impoundments. They do have an increased risk for acid rock drainage generation though due to the increased oxidation potential.

For stacks built on permafrost, typically the tailings also freeze and become permafrost themselves, minimizing water flow and reducing the risk of physical or chemical reactions within. There is also less winter water management required because the facility itself is not storing water. Tailings stacks behave more favorably to potential differential settlements from ice-rich permafrost thaw in the foundation vs. a traditional embankment dam. In order to assess these benefits, understanding the permafrost thermal profile within the foundation and as it grows into the stack is vital for modeling these structures.