by Hayley Croteau, P.Eng.

(Originally published in Canadian Geotechnique Magazine | Summer 2022)

“Because temperature changes can be indicative of other processes occurring within the ground, these sensors [temperature cables and thermistors] can provide useful data to engineers when site conditions start to change.”

Introduction

Ground temperature profiling in the geotechnical instrumentation and monitoring industry has historically been used mainly on projects in cold regions. This has included infrastructure built on permafrost, like buildings, bridges, landfills, highways and winter/ice roads, as well as mines and oil and gas facilities in similar climates.

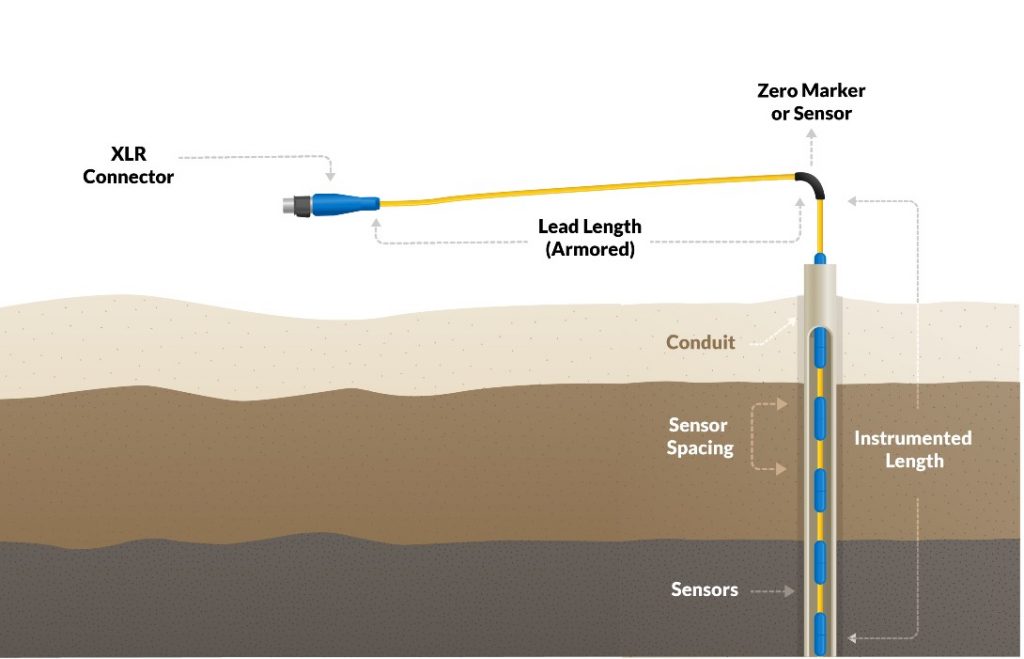

Temperature sensors (thermistors) are installed at multiple positions along a single cable in a borehole and used to monitor ground temperatures at specific depths (Figure 1). Most manufacturers customize the cables to the project specifications. Data collected is used to determine temperatures over time.

Historically, northern infrastructure was often built assuming the underlying permafrost would remain frozen over the design life, but temperature increases due to climate change have been threatening that assumption. While ground temperature profiling will remain an important part of future projects in the north as the climate changes, there are many other suitable applications in areas where permafrost is not present.

The instrumentation required for these non-conventional applications is the same as that required in cold regions and, therefore, commercially available digital temperature cables and thermistor strings can be used. Most thermistors on the market are rated to at least +80°C/176°F, while some can measure up to +125°C/257°F, meaning they are well suited for applications above the freezing level. A selection of these non-conventional applications is described in more detail below.

Infrastructure

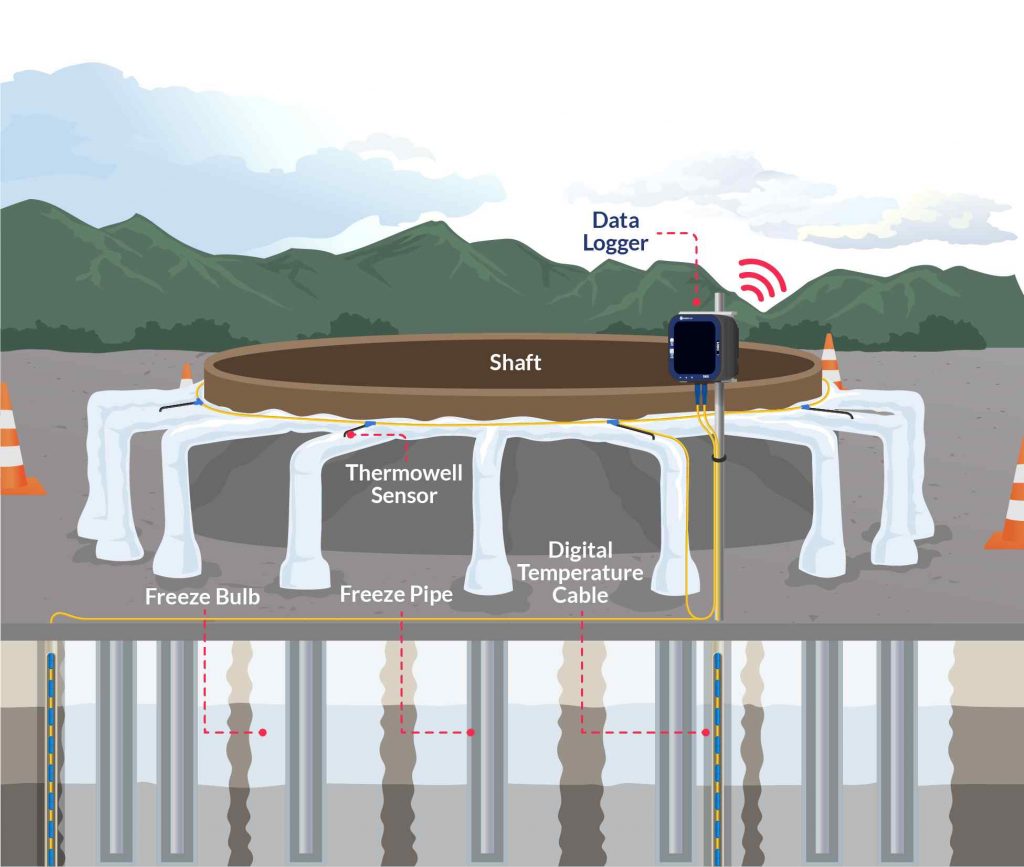

Artificial ground freezing has been gaining popularity in construction, including for shafts and safe havens on tunnelling projects. Chilled liquid is circulated through vertical pipes in the ground, freezing porewater and creating a freeze bulb around each pipe. The pipes are installed in closely spaced patterns so freeze bulbs can grow and merge together to create a frozen underground wall (Figure 2). Ground freezing can be used for excavation support, especially where traditional methods such as diaphragm walls are not feasible. It also is an effective way of controlling groundwater in excavations.

Ground freezing can take many weeks to build the frozen wall at the target depth. A critical part of the monitoring program is vertical temperature profiling within and around the frozen zone. Temperature cables with dozens of thermistors collect data and allow the project team to model the frozen bulb development. Additionally, sensors are used to monitor temperatures in the fluid lines leaving the cooling plant and returning from the ground, allowing heat transfer to be evaluated. The data are critical to verify that the ground has frozen as designed and to allow construction to proceed safely. The return on investment (ROI) of a real-time monitoring system can be measured against cost reductions gained by shortened construction time, minimizing standby and eliminating unnecessary freeze plant energy consumption.

Highways, roads and railways in northern climates can be subject to dangerous conditions during winter and subject to weight restrictions during spring thaw. Both of these concerns apply to infrastructure built over permafrost and to infrastructure that is not. Road weather information systems (RWIS) are gaining popularity within government highway organizations as real-time transfer of data becomes easier and more cost effective, even from remote locations. Data collected includes atmospheric conditions and both pavement and shallow ground temperatures. The data are used to assess current conditions and to develop forecasts, allowing departments to warn drivers via Intelligent Warning Signs along affected corridors or to implement mitigation strategies, such as plowing or sanding.

Seasonal road weight restrictions have historically been applied by highways departments based upon prior observations and not on real-time data. Changing climatic conditions mean that historical observations may no longer be representative. Heavy vehicles and commercial transport trucks are

affected during these restrictions, resulting in extra costs to their clients due to reduced loads and additional trips. Ground temperature cables, with automated data transfer, installed in strategic locations along a highway network allow for the department to monitor the timing of ground thaw and to enact the restrictions based upon real-time data.

Slope creep movements in cold climates have a tendency to slow or stall during winter months as the shallow subsurface freezes and restricts infiltration of surface water and precipitation. During spring, instrumentation such as inclinometers and ShapeArrays (SAA) can often detect increased movements as the ground thaws and infiltration resumes. Ground temperature cables can provide an early indication of spring thaw and potential increased creep rates and can complement the data observed in other installed instrumentation. A temperature cable installation only needs to be as deep as the expected frost depth and can be installed in a small diameter borehole, making it relatively easy to add to a site.

Geothermal energy production and geothermal heating/cooling systems are gaining interest as renewable energy sources. Geothermal energy production (electricity) relies on heat within the earth to generate steam to drive turbines. In places like Iceland, where the heat source is shallow and abundant, geothermal plants have been in operation for decades. For other places, such as a pilot project in Saskatchewan, Canada, holes must be drilled to a depth of over 3 km/1.9 miles to reach the heat source. These types of geothermal applications typically exceed the temperature specifications of conventional geotechnical instrumentation sensors.

In addition, research and implementation is ongoing for shallow geothermal systems for heating and cooling buildings. In this application, a heat pump circulates fluid through piping in the ground. During the winter, ground heat is brought into the building and during summer the reverse occurs. Heat exchange piping can be installed in shallow excavations, where space permits or otherwise in vertical drill holes, sometimes up to hundreds of metres into the ground. Monitoring ground temperatures during operation of these heat exchange systems is important to observe the energy transfer and changes in subsurface temperatures over time. Ground temperatures encountered are typically well within the range of conventional geotechnical temperature cable specifications and they can be installed within trenches for horizontal systems or in boreholes for vertical systems.

Mining

Artificial ground freezing in mining uses the same principles as it does for civil infrastructure tunnelling projects but on a much larger scale. It has been used for underground uranium mining operations and potash mine shafts, where the target zone can be up to 1000 m/3281 ft below ground surface, and the designed frozen volume can be as large as the entire ore body plus the overburden combined. The purpose of the freezing is to prevent groundwater flowing in, to prevent contaminated water from flowing out and/or to improve the stability and mechanical properties of ground conditions.

Vertical holes are drilled in tight patterns from the surface to the target depth and cooled liquid is circulated into the installed pipes. Alternatively, a crown pillar can be frozen by drilling and installing freeze pipes upwards from an under ground opening. Freezing of the ground can take years (vs. weeks for infrastructure applications), requiring long-term monitoring of the freeze bulb development. Similar tempera ture cables are used to profile the ground but due to the high water pressures often encountered at these depths, and potential exposure to corrosive heat exchange fluids, such cables are typically installed inside a sealed conduit to provide additional protection during the duration of the freeze program.

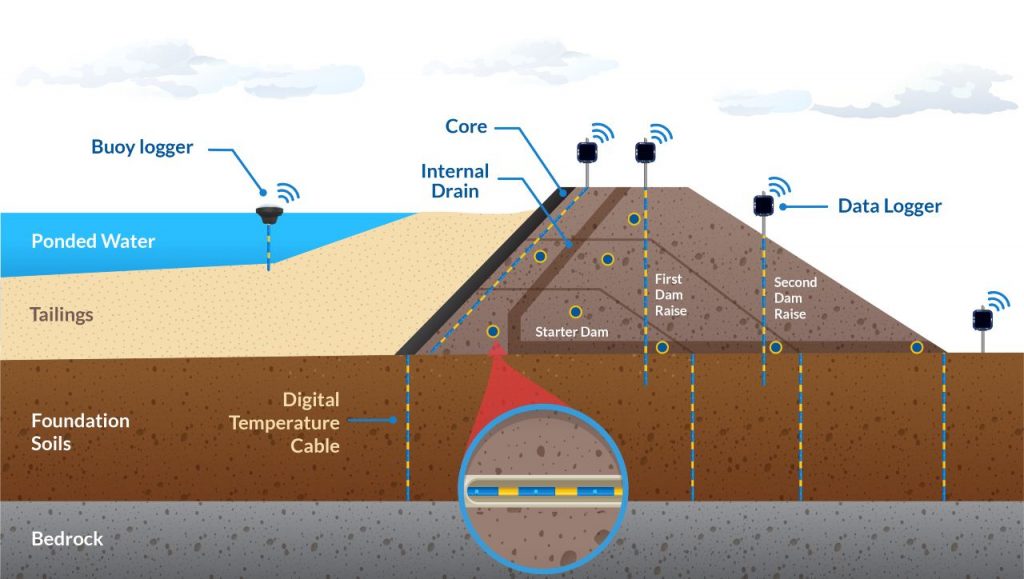

Tailings and embankment dam seepage. While perhaps not an intuitive use for temperature cables, temperature data can provide another tool for monitoring seepage of tailings storage facilities (TSF) and other embankment dams/levees. Impounded water seasonally varies in temperature and when it leaves the tailings pond or reservoir and travels through the dam, it will carry the temperature of the tailings pond/reservoir. These temperature signatures can be used to detect seepage more easily and more cost effectively than other means.

Temperature cables can be installed within the dam either horizontally, as the dam is built, and/or vertically, either during or after construction (Figure 3). For existing dams, the cables can be grouted into abandoned standpipes or inclinometer casings, or buried horizontally along the toe, avoiding the need to drill. To capture spatial variability of seepage, many thermistors are typically installed along each cable, spaced close enough for the dam engineer to monitor seepage changes and patterns. Horizontal cables are often installed at multiple elevations to monitor vertical variability. The reservoir temperature is also recorded for reference.

As water seeps through the dam, the temperature cables measure the seasonal variations, albeit with a time offset from the temperatures observed in the reservoir. Dam engineers monitor the data for changes in this time offset because a shorter time period can be an indication of increased seepage. Also, temperature changes within a particular area of a dam can indicate a change in the flow path. If changes are observed, the engineers can take action to investigate further and implement any required mitigation strategies.

Acid mine/rock drainage can occur in waste dumps or TSF, or in other exposed rock in mine workings, when sulphides oxidize after being exposed to oxygen and water. Acid generation can occur over many decades and can contaminate the surrounding environment when acidic waters flow from the mine workings. These acidic waters can also mobilize heavy metals and transport them into the environment, affecting local plants, animals and waterways.

The sulphide oxidation process can be monitored by insitu instrumentation, including temperature cables, to look for increased temperatures indicative of the process. These temperature cables are installed within monitoring wells in the waste dump or TSF, with each cable having multiple thermistors at different depths. The resulting temperature data can help in identifying hot spots within the facility, both via depth along each cable and across the facility via installing multiple cables, and allow the project staff to assess areas of concern and take further steps to address the acid generation.

Conclusion

The applications described in this article are just a starting point for using ground temperature cables and thermistors. Because temperature changes can be indicative of other processes occurring within the ground, these sensors can provide useful data to engineers when site conditions start to change. While temperature cables haven’t been a common tool in the Instrumentation and Monitoring toolbox, except in cold regions, going forward they can provide useful, complementary data along with other common geotechnical instrumentation.