What is artificial ground freezing?

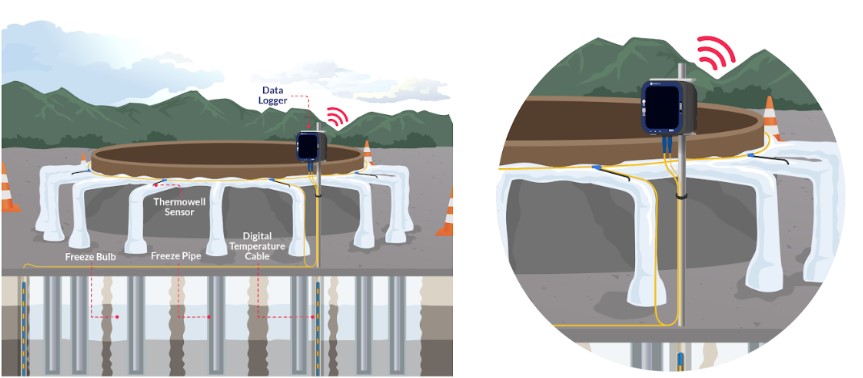

Artificial ground freezing is an engineering technique that is commonly used for groundwater control and/or excavation support for shafts and tunneling projects, and mine sites1. It involves drilling closely-spaced pipes into the ground and then running coolants, such as chilled brine between -25 °C and -35 °C, through them to extract heat from the ground and form a wall of frozen pore water (see Figure 1). This process offers temporary support, making it possible to safely excavate and construct underground structures 2.

Ground freezing is an incredibly sustainable and environmentally-friendly technique compared to conventional methods, such as diaphragm walls, which use chemicals and other grouting materials, while freezing uses a closed-looped brine system, releasing no hazardous material into the surrounding environment. Additionally, it creates a durable, waterproof barrier around the excavation site, thus eliminating the need to remove and treat any groundwater. This greatly reduces the risk of contamination seeping into neighboring areas, lowering the risk of environmental issues3. Provided that a clean source of electricity is available at site to power the freeze plant, it also has a much lower carbon footprint than using concrete products for ground shoring4.

Ground freezing for civil construction projects, which are usually a few hundred feet deep, requires a few weeks to a few months to freeze, while freezing for mining projects, which can reach depths of over 3,000ft, can take years5. Temperature sensors are placed within or near frozen zones (see Figure 2) to monitor the ground temperature, the frost expansion, and the heat transfer from the ground to the cooling plant. The temperature monitoring data is stored on a web-based platform and can be viewed at any time. The ground temperatures are used in modeling software like Temp/W to assess the development of the freeze bulb. This data is vital to ensure the ground has frozen to specifications and to verify when it is safe to start excavation4.

Digital thermistor strings for real-time ground temperature monitoring

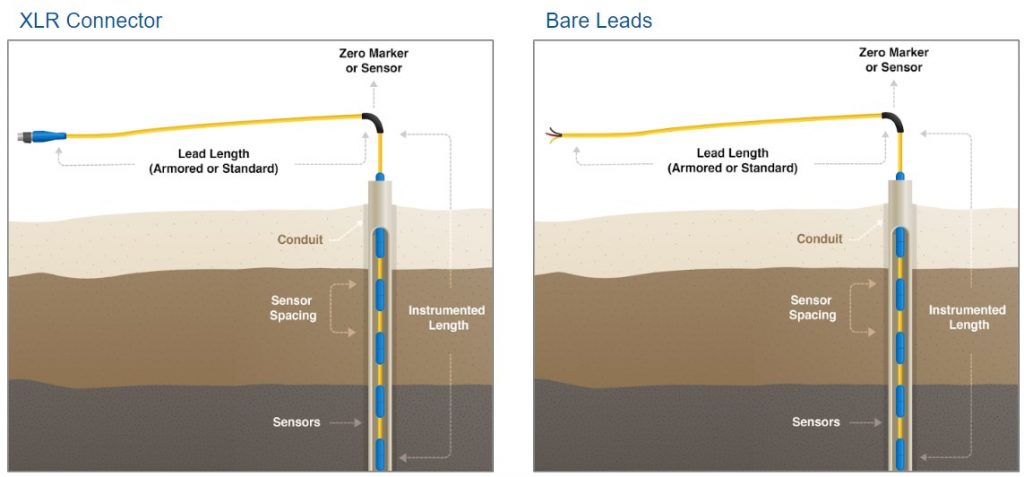

While there are many types of temperature sensors available, digital thermistor strings have many advantageous features suitable for deep ground freezing. They can accommodate up to 125 sensors over 750m length without increasing the cable’s diameter, as each sensor is digitally addressable on the same set of three conductors. This is in contrast to analog temperature cables, which need a separate pair of conductors for each thermistor, resulting in a thicker cable with more sensors and a practical limit of 15-20 sensors per cable. Therefore, digital thermistor strings‘ compact design makes them ideal for deep ground freezing projects that require many sensors to measure temperatures at various depths.

In addition, digital temperature cables offer an easier process for temperature measurement than analog thermistors. These cables store calibration offsets on the sensor board, which eliminates the need for data post-processing. Analog thermistors, on the other hand, require taking a measurement of the thermistor’s resistance and coefficients to convert the data into a temperature reading, which must be done either within the logger or through data post-processing. Digital thermistor strings provide a rapid and reliable way to measure the temperature of frozen soil curtains, enabling real-time monitoring.

There are two common configurations of digital thermistor strings used for monitoring ground freezing:

Ground temperature monitoring

Digital thermistor strings installed in vertical drill holes in between and around the freeze pipes (see Figure 3). For horizontal ground freezing installations, such as for tunnel cross passages, these same cables can be installed in a horizontal fashion.

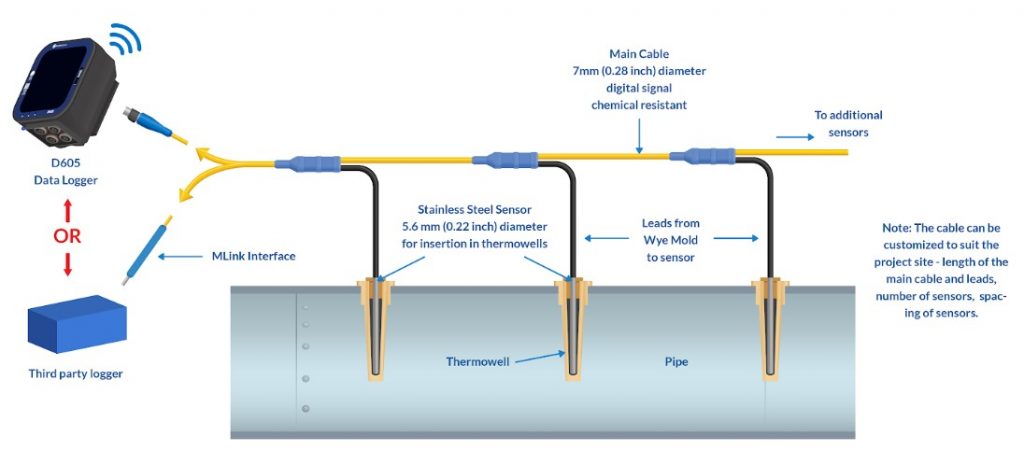

Freeze pipe heat transfer monitoring

Temperature sensors digitally bussed on a common cable but with each sensor offshoot from the main cable to allow for installation within thermowells along the freeze pipes coming out of the freeze plant and as they return from the ground to assess the heat extraction from the ground(see Figure 4).

On a recent outfall tunnel ground freezing project (see Figure 5), for instance, real-time temperature profile readings provided invaluable data that helped the project team effectively model and analyze freeze bulb progressions and to determine the ideal time to start excavation of the shaft.

By using our digital temperature cables with 25-31 sensors per cable, the client was able to successfully monitor the freeze bulb and the removal of heat from the ground via thermowell cables with 20 sensors each. Our 0.28in. (7mm) diameter, 3 conductor cables replaced the bulky thermistor strings, allowing the client to avoid the limitation of 15-20 sensors maximum per string. Furthermore, our cables only required one data logger channel per cable as opposed to one data logger channel per sensor like the traditional thermistor strings. This enabled the client to reliably collect the data needed and streamline the temperature monitoring process.

Custom-Built Digital Temperature Cables for unique ground freezing challenges

Ground freezing has proven to be an invaluable tool for the mining industry. At Saskatchewan’s largest uranium mine, an impermeable wall was constructed to prevent water from entering the mine site. This not only reduced water inflow, but also saved the company millions of dollars in lost mineral reserves and increased material costs. It also prevented future production suspensions, allowing the company to realize improved efficiencies and reduced risk6.

Freezing the ground at mining sites can take years, and requires careful monitoring of the freeze bulb development. Digital temperature cables are also used to profile the ground, but they must be installed inside a sealed conduit to protect them from large water pressures experienced in deep installations and long-term exposure to corrosive heat exchange fluids when installed inside the freeze pipe system. This ensures the freezing process can be safely monitored over the duration of the project.

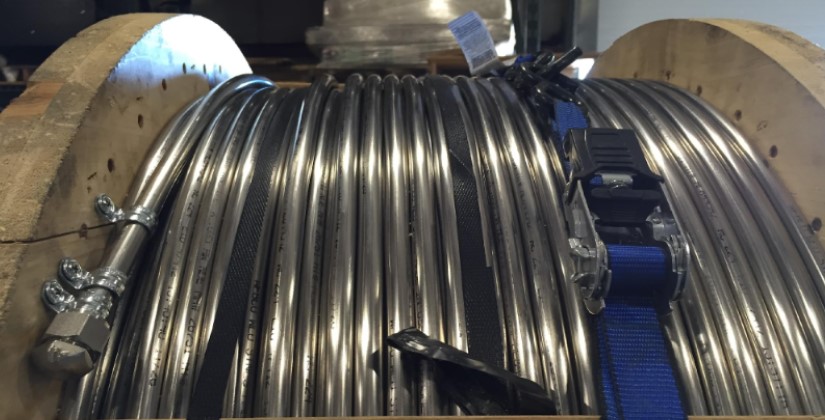

As an example, beadedstream was tasked with providing a temperature monitoring solution for a client’s underground uranium mine in Saskatchewan, Canada. The chosen method of ground freezing, which mitigates the risk of water inflow and stabilizes weak rock formation, utilized a 30% CaCl solution pumped from the surface. The temperature monitoring needed to confirm the effectiveness of ground freezing, ranging from -5 to -20°C (-4 to 23°F). The 100-120 holes in each production panel took 2-5 years to freeze the ground. The temperature sensors had to be robust enough to withstand an extremely challenging environment of 5.5MPa/800psi fluid pressures at the bottom of the hole with a minimum temperature of -40°C (-40°F) and exposure to 30% CaCl brine.

We overcame the challenges presented by the client’s site needs through the production of custom-made temperature cables. Our cables, 457m/1500 ft in length were placed inside a continuous length of stainless steel conduit with custom sensor molds and pre-loaded onto custom reels for rapid installation at the site (See Figure 6 and 7). Furthermore, the sensors were integrated with third party SCADA systems. This allowed the customer to use our cables for each phase of their ground freezing project and monitor the temperature data to ensure the ground had reached the right temperature before active mining commenced.

In a nutshell

As the need for sustainable construction projects continues to increase, so too will the use and implementation of artificial ground freezing and digital temperature monitoring instruments. Digital thermistor strings have made temperature monitoring much easier, safer, more environmentally-friendly, and cost-effective. This allows collection of accurate, real-time data and has enabled the execution of numerous successful and safe ground-freezing projects.

beadedstream offers temperature monitoring solutions for ground freezing projects through its digital temperature cables, data loggers, and beadedcloud real-time monitoring app. Whether you are a contractor, civil or mining engineer, or researcher in need of reliable temperature monitoring, contact beadedstream today at contact@beadedstream.com to discuss your project needs.

References:

1Keller. (n.d.). Ground freezing. https://www.keller-na.com/expertise/techniques/ground-freezing

2Kajastie, N. (2022, November 29). How artificial ground freezing works as a ground improvement technique. https://www.geplus.co.uk/features/how-artificial-ground-freezing-works-as-a-ground-improvement-technique-29-11-2022/

3Power, M. (2016, November 8). Ground Freezing is Environmentally Friendly Shoring Option. https://www.greenbuildermedia.com/blog/ground-freezing-an-environmentally-friendly-and-time-saving-shoring-option

4groundfreezing.com. (n.d.). The Importance of Artificial Ground Freezing (AGF) for Shaft sinking and tunnelling. https://groundfreezing.com/featured-ground-freezing-news/ground-freezing-for-shaft-construction/

5Newman, G. et. al. (2011). Artificial Ground Freezing: An Environmental Best Practice at Cameco’s Uranium Mining Operations in Northern Saskatchewan, Canada. https://www.imwa.info/docs/imwa_2011/IMWA2011_Newman_253.pdf

6Cameco.com. (2010). 2010 MD&A:Our operations and development projects.

6Cameco.com. (2010). 2010 MD&A:Our operations and development projects. https://www.cameco.com/annual_report/2010/common/pdf/mda/Cameco_AR_2010_MDA_Operations_Development_projects.pdf