Golder Associates

Milne Point,

Alaska,

USA

linkedin/beadedstream

844.488.4880

www.beadedstream.com

contact@beadedstream.com

Watch case study

The design of a subgrade wash pit at a grind and inject facility required thermal modelling and specific design considerations to protect against permafrost thaw due to 50°F (10°C) fluid to be offloaded in the pit during operation.

Temperature monitoring was included in the design to confirm the effectiveness of the insulation layers and thermosyphons in the foundation and to allow for proactive maintenance as required over the 20 year design life.

Click for an instant live demo of the beadedcloud data dashboard for FREE.

Free DemoApplication

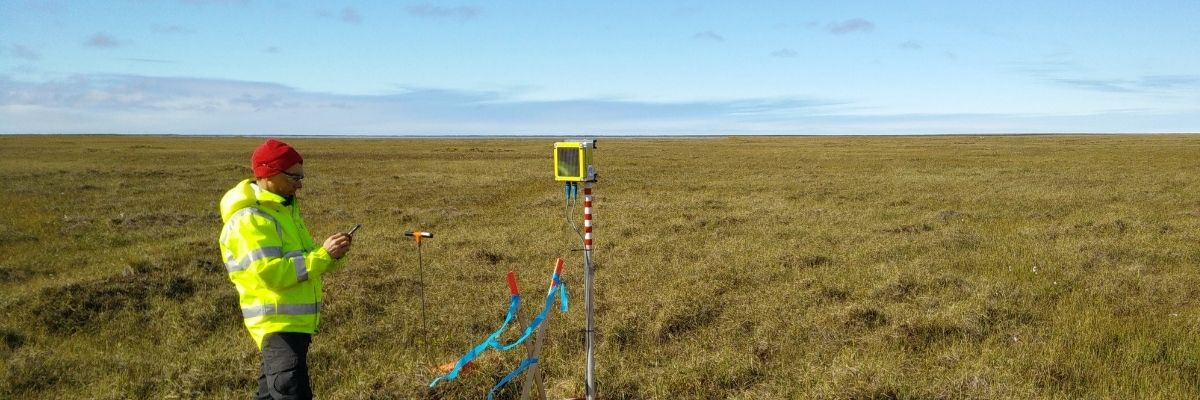

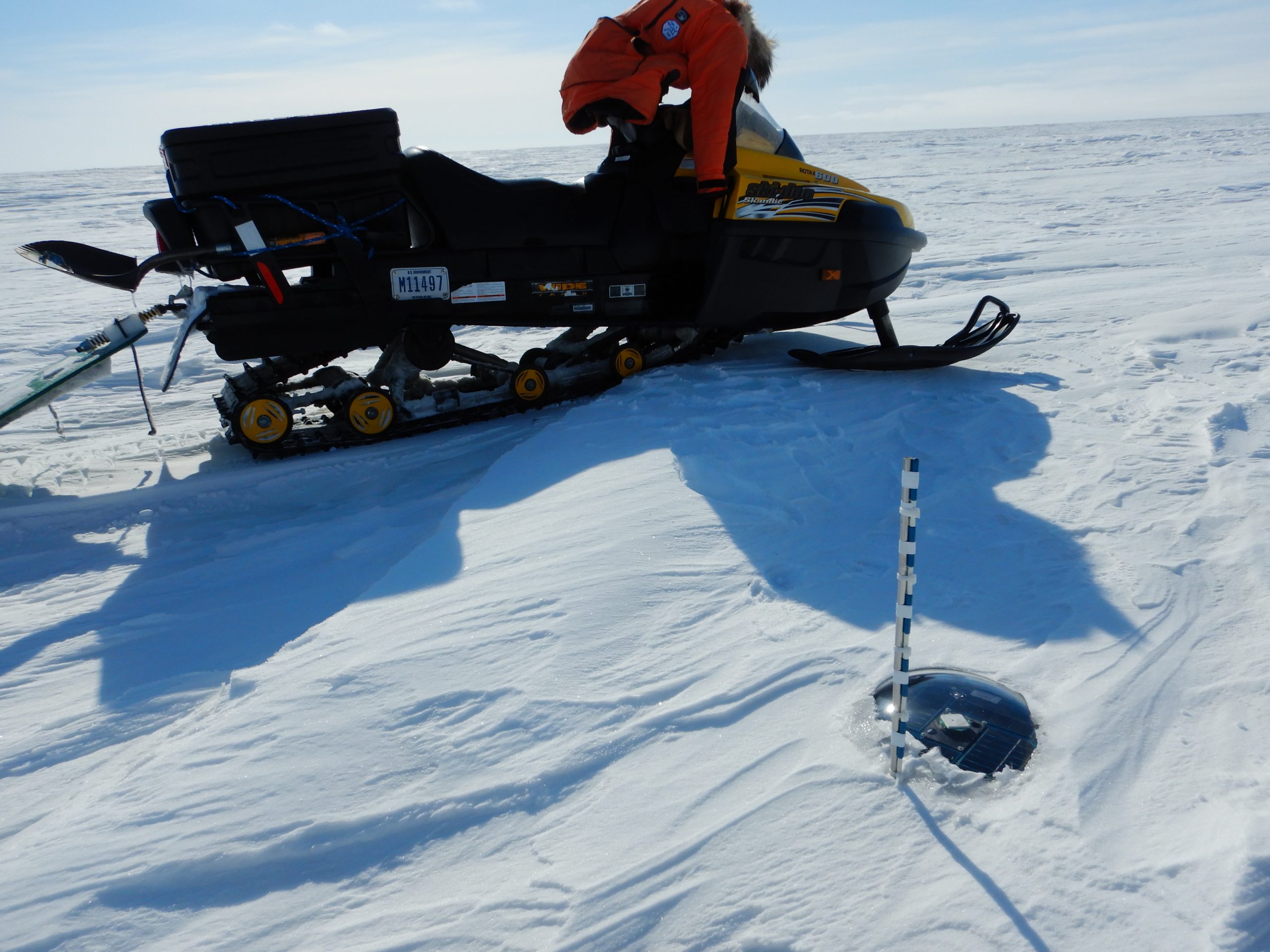

As part of a grind and inject facility developed on the North Slope of Alaska, an at-grade truck off-loading tent was included in the plan with a subgrade wash pit. The entire facility was built on ice rich permafrost and the wash pit invert was only 0.5 ft (15 cm) above the permafrost. The facility had a 20 year design life.

Disposal trucks off-load 50°F (10°C) fluid into the wash pit and could thaw the permafrost without specific design considerations. Golder’s scope was geotechnical engineering and thermal modelling for the project. The design included insulation layers and they worked with Arctic Foundations Inc. to design a passive thermosyphon system to be used in the foundation of the off-loading tent.

beadedstream Solution

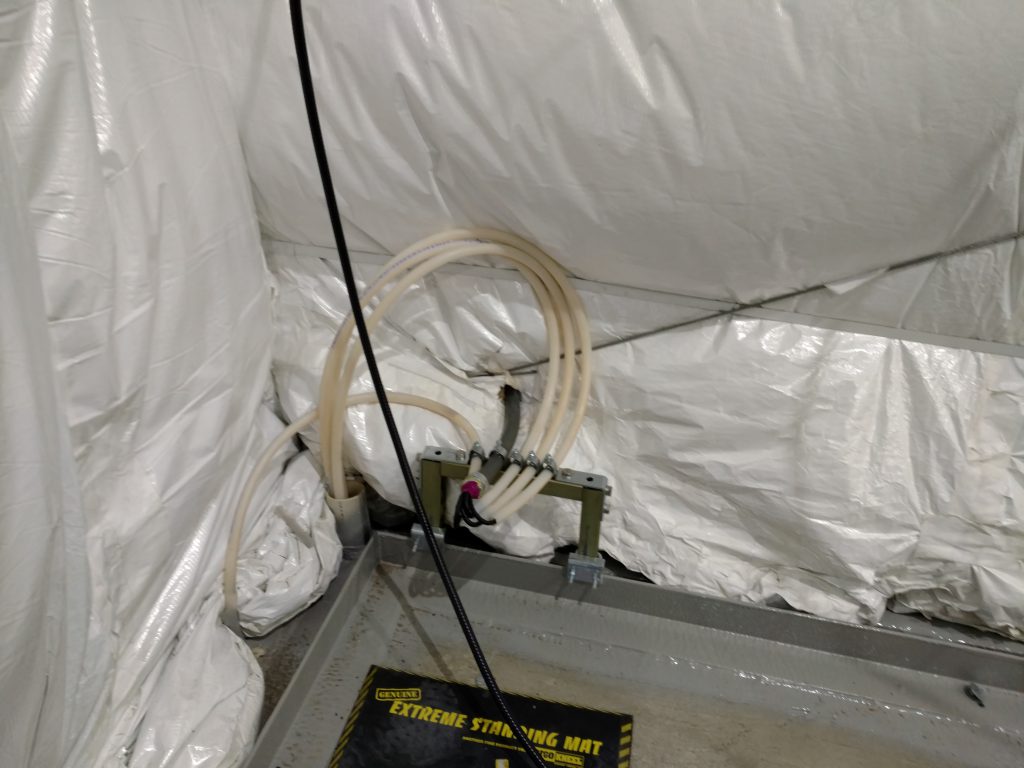

A monitoring solution was required to confirm the performance of the passive cooling system as the facility went into operation, considering the 20 year design life requirement. Golder installed 4 Digital Temperature Cables in the subfloor of the structure to monitor temperatures over time. The cables were installed in conduit to protect them from damage over the life of the project.

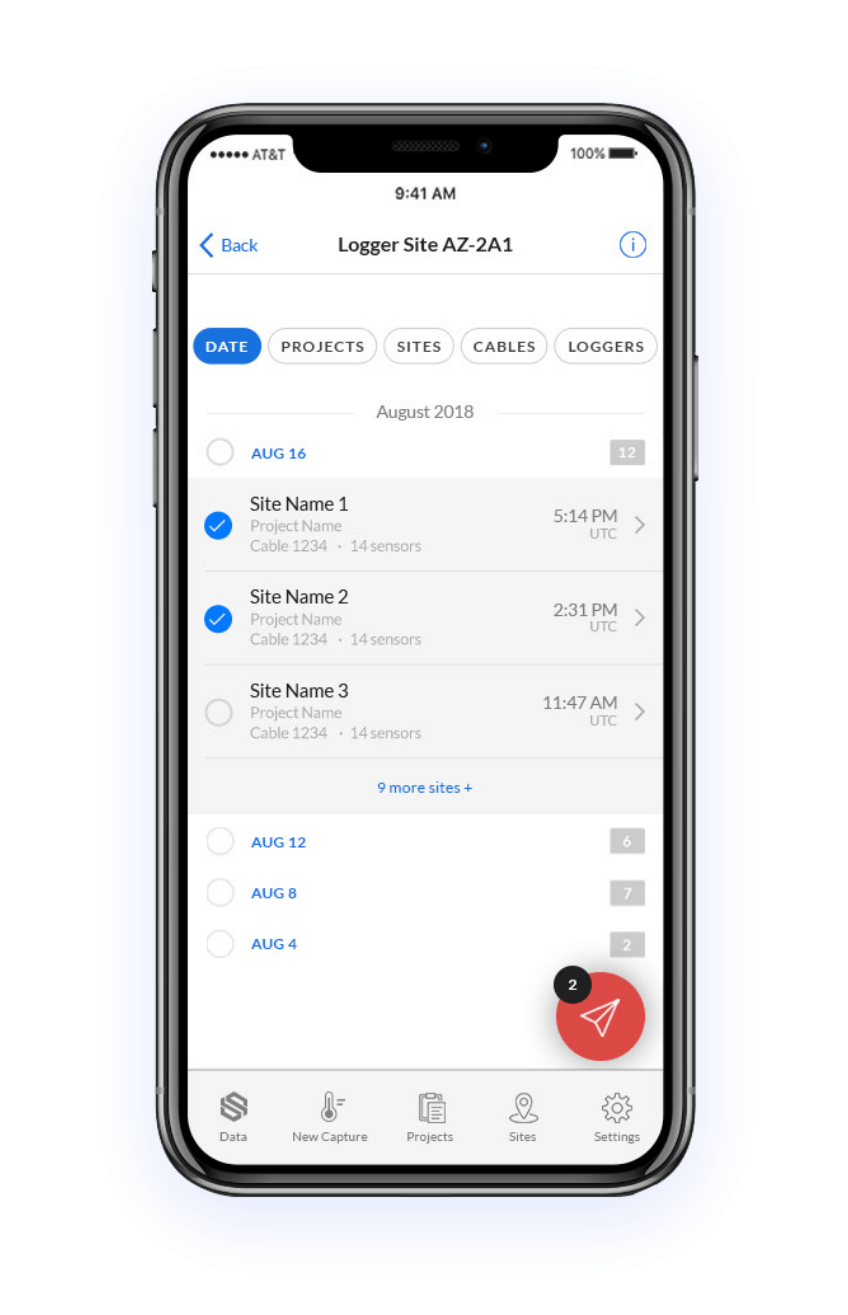

The cables were connected to a D405 Data Logger which was installed in a custom panel box to provide power and security to the logger at site. In this case, they decided to download data manually off the logger periodically using Bluetooth and our Capture Mobile iOS app, rather than enabling the satellite modem.

beadedstream Solution Benefits

The beadedstream solution fit the needs of the design life of the project and allowed them to monitor temperatures along 4 cables. By using a custom panel box, the logger was secure and powered for the life of the project without needing to rely on solar energy to recharge it. The Capture Mobile iOS app was easy to use and allowed on site personnel the ability to download the data and send it to Golder’s office in Anchorage when needed.

By monitoring the temperatures in the sub-floor, proactive measures can be implemented if temperatures rise, saving costs for the operator in the long-term vs. reactive remediation for issues such as differential settlement due to permafrost thaw.

Featured Product

Capture Mobile App

Capture by beadedstream is beadedstream’s free iOS app and allows users to talk with their beadedstream devices

View ProductExplore Our Most

Recent Case Studies

Learn about our most recent projects and how beadedstream’s products were deployed.