When it comes to protecting your digital temperature cables, beadedstream places great emphasis on the use of conduit. In this article, we will delve into the reasons behind this recommendation, highlighting the benefits and key considerations for different applications. By understanding the importance of conduit, particularly in remote and challenging environments, you can ensure the longevity and accuracy of your temperature monitoring projects for years to come.

Physical Protection

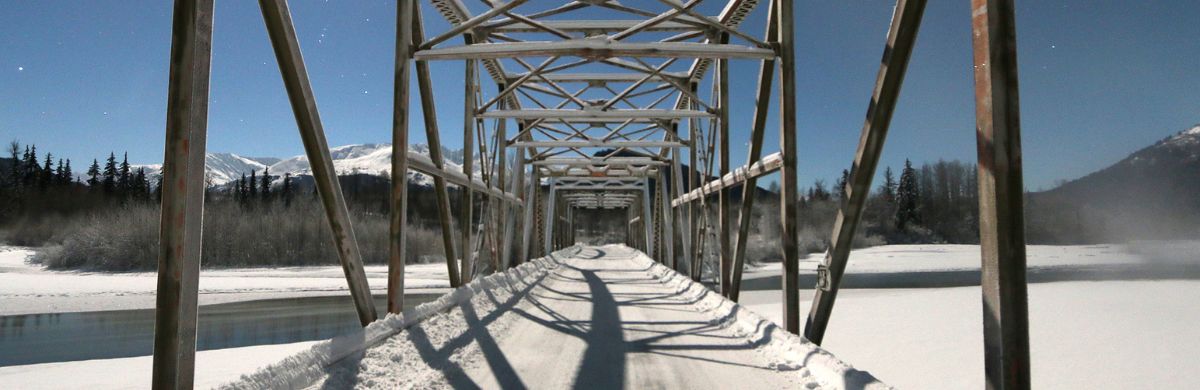

Conduit serves as a physical shield, safeguarding your cables within the ground and at the surface. This is particularly essential for long-term monitoring projects and remote environments where exposure to various elements can pose risks. By enclosing our digital temperature cables within conduit, you enhance their durability and resistance to differential ground movements occurring over short distances, impingement from large aggregate (cobbles and boulders), frost heave, permafrost thaw, and potential damage caused by wild animals or heavy equipment (See. Fig. 1).

In cold applications, installing temperature cables inside completely sealed conduit reduces the risk of water entering the conduit and freezing. If water is allowed inside the conduit, and later freezes, large strains may be imposed on the temperature cable as the water expands, potentially damaging the cable or making it difficult to remove in the future, or both. Alternatively, silicon oil, with its low freezing point, is sometimes used inside the conduit to prevent fluids from freezing within the tubing/pipe. However, additional complexity and the risk of silicon oil leaking into the environment make this option less common than in the past.

Data Integrity

One of the primary reasons we strongly recommend conduit is to ensure the protection and integrity of the temperature data. Ground movement, vehicle traffic, or animal interference can potentially damage the thermistor string conductors, outer insulation or both if left exposed. Utilizing conduit significantly reduces the risk of cable shearing or damage, safeguarding the project’s valuable data. The cost of purchasing conduit pales in comparison to the potential consequences of data loss and the need for drilling new holes or replacing damaged cables.

Ease of Installation

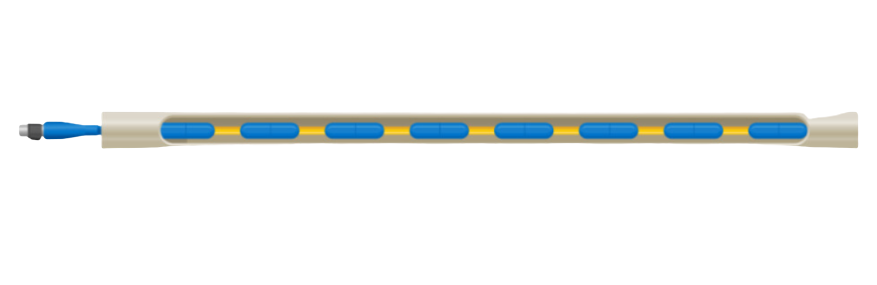

Our customers have the flexibility to either install their own pipes or conduit and insert our cables into them, or opt for the convenience of having us pre-install the cables into flexible conduit before shipping. With pre-installed conduit, the customer receives a neatly packaged solution that can be easily uncoiled and placed into the ground, saving time and effort during installation (See. Fig 2).

Conduit Options

PEX Conduit

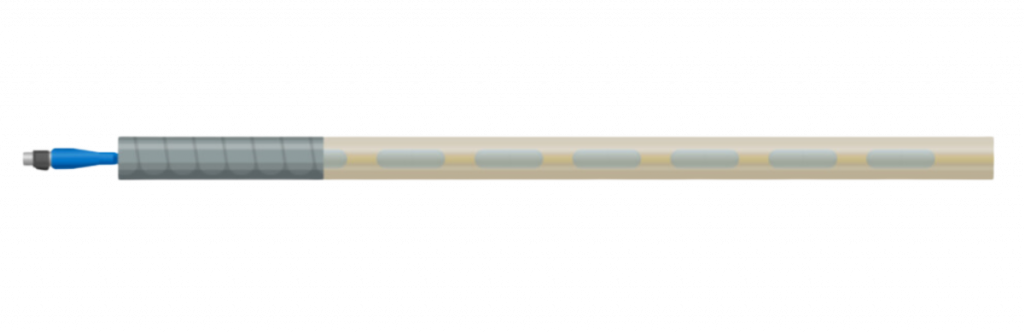

PEX conduit is the most commonly recommended option due to its versatility and effectiveness in the majority of shallower temperature monitoring applications. We typically utilize ¾ in.(1.9 cm) diameter PEX conduit, allowing our ½ in. (1.27 cm) diameter sensors to fit inside with minimal open annulus while minimizing any air flow that may occur between sensors within the hole (See Fig. 3). With the cable pre-installed at our facility, customers receive it conveniently coiled on a pallet, ready for straightforward installation.

This pipe is suitable for direct burial in the ground; however, due to its limited UV rating, it is not recommended for long-term surface installations. To address exposed cabling, we transition to a flexible conduit that offers optimal UV resistance and protection (See Fig. 4). For longer lengths, we include 1 in. (2.5 cm)+ diameter fittings every 250 ft (76 m) lengths to join additional pieces of conduit together.

In most applications, we leave the annular space between the cable and PEX conduit open but seal the ends of the conduit to minimize air circulation. However, in specific scenarios like submerging the temperature chain in streams or rivers, we offer the option to fill the annular space with sand, increasing the cable’s weight and ensuring it stays at the bottom.

1 in. (25mm) PVC Pipe Conduit

For the in-ground portions of temperature cable installations, some customers opt to source and install 1 in. (25 mm) PVC pipe conduit themselves as an alternative to using PEX conduit (See Fig. 5). This choice allows for pre-installation of the conduit before the temperature cable may arrive and cost savings on freight. To further enhance the performance of the conduit, some customers choose to fill it with silicon oil, which has a low freezing point. By utilizing silicon oil, they ensure that the pipe remains open on the inside and is protected from freezing, providing added reliability and peace of mind in cold weather conditions.

HDPE Cable Shielding

For environments with acidic conditions or corrosion concerns, such as landfills, we offer the option of HDPE conduit, which provides additional protection and customizability (See Fig. 6). This shielding is waterproof and rugged, making it ideal for more robust shielding, especially for the exposed-to-air section of the cable. It is also specifically designed for direct burial, further enhancing its suitability for various ground monitoring applications.

Stainless Steel Conduit

For installations involving high fluid pressures (such as deep water wells), or in the presence of chemicals that could damage the temperature string, we recommend stainless steel conduit (See Fig. 7). This robust option is ideal for deep installations and environments with corrosive elements, offering complete sealing to prevent fluid ingress. It is also waterproof and rugged, allowing for completely sealed runs of up to 2,500 ft (762 m) with orbital weld joints or Swagelok fittings. This makes it our toughest cable shielding option. The stainless steel conduit is shipped on a wooden spool for transport to site and installation into the ground.

Does the air inside the conduit impact the reading?

Conduits are typically sealed along their full length to minimize air circulation. Convective currents (i.e. “stack effect”) may interfere with readings, specifically for applications with tightly spaced sensors. The conduit diameter is also chosen to minimize the annulus between the sensor and the inner diameter of the conduit, reducing the ability for air flow.

Conclusion

Investing in conduit for our digital temperature cables is a critical step toward maximizing the reliability and longevity of temperature monitoring projects. By providing an additional layer of protection against various risks, conduit minimizes the chances of data loss, ensuring accurate and valuable insights. At beadedstream, we strongly recommend the use of an appropriate conduit to our customers, empowering them to overcome challenges posed by ground conditions, climate, and site-specific factors.

To learn more about how conduit can enhance your temperature monitoring projects, feel free to contact our team. Protect your data, mitigate risks, and ensure the success of your temperature monitoring endeavors with beadedstream’s temperature cable shielding features solution.